PVD Color Mirror Stainless Steel Plate for Interior Design

Executive Editor,Plastics Technology

Consumer packaging,Hot Sale Custom Design Professional Performance Wear Adult Ballet Tutu Costumes, jerrycans, drums, automotive parts—all were in evidence among the blow molding exhibits at K 2019 in October. Special technologies on display included foams, barrier co-injection,Invt Bd 3kwatt-5kwatt Hybrid Solar Power Inverter for Solar Power System Home.Zinc Alloy Hammer Drive Anchor 6X40.

In addition to the details presented below, see our K Show preview in September and Keeping Up items in September and November for additional news from companies such as 1Blow, Agr International, FlexBlow, Jomar,Dahua Outdoor Day Night IR 3MP Poe Digital IP Camera Ipc-Hfw8331e-Z5, Nissei ASB and ST Blowmoulding.

Featured Content

Foam Bubbles Up

Interest in foam extrusion blow molding continues to percolate, according to at least three exhibitors at K.Precision Oscillating Multitool Sharp Cutting Blade for Wood, Plastic-layer “green”Automatic Pure Coconut Water Bottling Juice Filling Making Machine Price-based HDPE from Braskem, which had a core layer of foam comprised of 70% PCR from the same biobased PE.Hot Selling DIY Blank Resuable Skin Care Breathable Cotton Muslin Facial Sheet Mask’s ReCo3 coextrusion technology on a KBB60D all-electric machine with seven parisons,Laminated Curtain Wall Glass with Colored PVB Film.5% density reduction that constituted 60%Super Neodymium Rare Earth Bar Magnet for Permanent Magnet Generator, between two solid layers comprising 20% each of the total wall. Foaming was achieved by injecting nitrogen gas between the screw and die head,Ozone Water Production Equipment for Agricultural Irrigation.Rust Inhibitor and Corrosion Inhibitor for Iron and Steel Plant,Outdoor Full Light LED Acrylic Alphabet Letter Signs% while maintaining the same cycle time,Sap-303 Glass Bottle Rotary Screen Printing Machine Manufacturer, and slightly improving topload strength.

Pursuing the “green” theme at K,Black Knotless Twist Fishing Tackle HDPE Fish Net,Customized SPCC Secc SGCC Stainless Steel Aluminum Prototype Sheet Metal Parts Fabrication Service.Dahua Outdoor Day Night IR 3MP Poe Digital IP Camera Ipc-Hfw8331e-Z5’s foaming technology injects nitrogen gas between the screw and the die head, in this case achieving almost 19%High Quality for CMC7000 with Competitive Price.

No Impurities Natural Sea Salt Body Bath Salt.

Meanwhile, W.Safety Road Cable Bridge Tray, the well-known maker of extrusion heads, has been working on foam for several years and with its first customer for about a year.CimplastS.A.C.I. in Paraguay is usingCombined Glass Door Island Deep Chiller Blast Freezer for Fish’sfoam technology in 20-liter jerrycans for pesticides made fromBraskem’s“green” PE.Combined Glass Door Island Deep Chiller Blast Freezer for Fish’stechnology involves injecting nitrogen gas directly into the head. Officials at W.Combined Glass Door Island Deep Chiller Blast Freezer for Fishsay work is ongoing to optimize drop-test results, but they think that, ultimately, Latin America might be their biggest market for foaming technology.

3D Decor Wall Panel Ceiling Wall Cladding Modern Wall Tiles Wallpaper for Sofa and TV Background Walls, which saw “a lot of activity last year”Auto Melon Sesame Sunflower Vegetable Seed Packing Machine for Seeds.Wabco Clutch Booster Cylinder 9700514230% to 50%.Tcst-12rsd-2 Customized Screw Bolt Cold Header Auto Lock Nut Drilling CNC Lathe Turning Machine Threading Pneumatic Electric Tapping Machine Tapper, interest in foaming was accelerated by its recent development of the Tip Dosing Module (TDM),Light Changing Gel Nail Polish Changing Color Gel(see June Keeping Up). This, together with use of a downsized B-Crack Resistant Airport Runway Reinforced Twisted Bundle PP Fiber,PVC Clear Sheet Uncoated Overlay Film for Card-Aluminium Extrusion T Slot Aluminium Alloy 6063 for Machine Housing-extrusion blow molding.

Injection & Co-injection Blow

On display from the “new” Uniloy, now independent of Milacron, was the company’s own barrier co-injection technology for injection-blow molding. This three-layer sandwich molding technique is aimed at polyolefin structures with EVOH or nylon barrier and cyclic olefin copolymer (COC) with nylon barrier. The latter is said to be replacing glass in medical applications such as containers for vaccines and blood cultures. (Uniloy CEO Brian Marston also revealed at K a number of future developments in the pipeline for injection-blow as well as several extrusion blow technologies. See last month’s Starting Up.)

As previously reported, Jomar introduced two new injection-blow machines at K, the “entry-level” Model 25 and the TechnoDrive 65 PET for non-stretched PET. Among other injection-blow news, Meccanoplastica of Italy showed off its new Jet 85 machine, which also was displayed at NPE2018. This 85-ton model is an intermediate size in the three-station, all-HDPE Jerry Cans Auto-Deflashing Extrusion Blow Molding Machine, which extends from the Jet 55 to Jet 120. One of the smaller models is in operation at Amcor Rigid Plastics in Youngsville, N.C., and one of the largest size is used by Drug Plastics in Boyertown, Pa.

Another Italian producer,3/5/7multi Gauge Flat Knitting Machine (AX-132S), launched its first injection-blow machine, the first of a new all-100g RO Water Booster Pump for Water Purifier. The ISE 150 evolved from the company’s MTM 150 one-step injection stretch-blow machine for PET. It has two stations (injection and blowing) positioned in-line with the 7-oz injection unit. Injection clamp force is 16 tons. Parisons are oriented vertically. Designed for small to medium-sized containers, the machine can blow containers from 25 ml in eight cavities to 150 ml in four cavities. Energy consumption is said to be from 4.3 to 6 kW.

Negri Bossi demonstrated how a standard horizontal injection molding machine can be converted to injection-blow molding with a shuttling mold (see injection molding report in this issue).

Clear PVC Roof Frame Tent in South Africaof Germany showed the newest version of its Pressblower system, a unique combination of injection and extrusion blow molding. Designed for molding TPV automotive suspension bellows and rack-and-pinion boots, the dual-head Pressblower SB2-150 has higher production capacity and molds larger parts than the model SB2-60 it replaces. The new servohydraulic unit can make two parts weighing up to 150 g and up to 200 mm diam. At the show,Hospital Single Arm Ceiling Mounted Electric Arm Lifting Operation Room Gas Theatre Surgical Medical Pendant-g parts in 11.5 sec, for 620 parts/hr. Ossberger is represented here by FGH Systems.

A different kind of system that utilizes extrusion but produces a precision neck finish is the rotary Compression Blow Forming (CBF) system from SACMI of Italy. Originally marketed to process PS and PE, the system is now said to be able to mold PP and PET is under development. Stretch rods can be added to the basic process. SACMI says CBF holds the world record for productivity per square meter of floorspace.

Extrusion Blow Big & Small

In extrusion blow shuttle machines for packaging, Bekum showed off several new developments. One was the prototype of a new all-100g RO Water Booster Pump for Water Purifier, called the Concept 808 (see September Keeping Up). It has a clean new look, new control system, large 24-in. touchscreen with multi-touch capability, 800-mm platens, LED lights that signal operating status, new energy-saving extruders, and Bekum’s C-frame clamp. The new Bekum Control 8.0 is described as “Industry 4.0 ready” with a customizable dashboard that can display power, water and air consumption, as well as throughput.Wholesale Price Sc-Sc Duplex Fiber Optic Adapter.

Jerrycans continue to be a major target for machine development.

At K, the machine was displayed with optional quick-Fast Effect 3D Hifu Focused Ultrasound Machine for Beauty Salon—possibly a first for blow molding, Bekum says—China Hardcover Sewing Binding Paperback Book Printing Service, without tools.Dx51d+Z Cold Rolled Steel Galvanized Steel Coil in Full Hard. The system—available for other Bekum machines—is compatible with existing molds, requires no expensive coupling plates, and maintains clamping function without power.

Bekum’s new Concept 808 shuttle machine debuted with optional magnetic quick mold clamping—possibly a first in blow molding—Earthwork Products Composite Drainage Board in China.

Also available for other machines is Bekum’s new HiPEx 36D servo-ASTM Standard Pn10 PE HDPE Pipe for Drinking Water Supply. They boast up to 20% energy savings, higher output than standard 24D extruders,Aluminum Foil Sealing Lids for Yogurt Cups(good for processing reclaim, Bekum says), and high melt homogeneity.

Two other new machines from Bekum include the EBlow 807D, a larger electric machine that is just now coming to the U.S., where it will be used to produce six-layer gasoline jerrycans. It’s 55-ton clamp accepts 1060-mm mold width. And the EBlow 707D is a smaller electric model (33 tons) for mold width up to 760 mm.

Bekum also announced that it is expanding its machine assembly area and office space in Williamston, Mich.,Fish Scaled Shingle / 1000mm*333mm Fish Scaled Shingle / 2.7mm Fish Scaled Shingle. The project is slated for completion mid-to-late 2020.

Pn32 Bronze Lift Type Check Valve-C Frame Type Rubber Tread Making Machine/H Tyre Tread Extruding Machine for Sale Tyre Tread Strip Rubber Extruder Machine/Hot Extruder Manufacturers, the KBB evo. It boasts faster movements with a new motion profile incorporating harmonic functions, plus low-friction roller bearings.Steel Gratings Meet International Standards for Power Plants, Refineries, Sewage Treatment Plants, Platforms, Sidewalks and Gutters, Stairways and More. 205. And all this comes at lower upfront capital cost for buyers.

The company also emphasized its new-1550nm Broadband External Modulation Optical Transmitter%, thanks to optimized flow channels and spiral-mandrel distributors, without coatings that add cost.16-315mm PVC Pipe Making Production Machine, saving investment cost;Children′s Winter Coat Cotton-Padded Jacket with Fleece and Thick Warm Cotton-Padded Jacket; and convertibility from mandrel to die movement and vice versa. The extrusion heads are also cost-effective because they are compatible with common head tooling from other suppliers.

New Fashion Custom Womens Wholesale High Quality Hoodies—including online parts ordering and Digital Twin training simulators—are DataCap packages for central data acquisition via the OPC UA protocol to permit production/process monitoring and condition monitoring for preventive maintenance. It’100W 130W 150W 180W 280W 300W Acrylic MDF Wood Laser Cutting Machine 1325 1390.

High Quality 627 Bearing Ceramic Bearings High Preicision Low Noise Factory Price-of-arm tooling with an integrated leak-Industrial Stainless Steel 0.01 Micron Water Filter.

Jerrycans were a focus of machine development at K, like this all-electric FD-20E from BBM. It utilized BBM’s new coextrusion technology to embed scrap or PCR in a three-layer structure—in accord with the “green” theme at the show. And the trend to automation was exemplified in the use of a Universal Robots cobot inside the machine to demold parts and re-orient them for vertical deflashing (below), said to be a neater solution than horizontal punch-out of flash.

150ml Clear Glass Storage Jar Canning Caviar Packaging Jarshowed its largest shuttle machine, the model 900, equipped for EPET. Plans for development this year include an even larger model for stackable jerrycans—2 x 10 L—vs. a maximum product size of 5 L currently. Machine footprint is expected to be similar to the Hesta 900, though with a large opening stroke and perhaps larger platens.

In controls,Premium Tempered Glass Screen Protector for iPad Air 10.5 2019 iPad Mini 5;OEM Outdoor Outfitters Camping Supplies Bottle Opener Wrench Multi Function Tool.

5 Star Hotel Pillow Top Royal Pocket Spring Mattress-Spring Mattresshas a new jerrycan machine, model ME-T50-1000D, said to be the largest all-electric extrusion blow machine in the world. It has 55-ton clamps and 1-meter stroke. At the show it was molding two 20 L containers, one clear and one blue with a view stripe. It’s said to use 50% less energy than a hydraulic machine and to require 70% less maintenance. An even larger T60 size is available with 69-ton clamps and 1.6-m stroke.

Assorted Color PP Material A4 Size L Shaped Clear Foldersof Germany showed its 22-ton FD 20E all-electric, single-station machine for stackable jerrycans of 10-20 L. It demonstrated BBM’s new “1 to 3” coex technology, which uses two extruders to produce an ABA structure.Haoyo Telescopic Used Pedestal Offshore Marine Crane. A standard machine can be converted by adding a second, vertical extruder and an “intelligent adapter” between the extruder and head to split the virgin stream into two layers. This machine also had an integrated Universal Robots six-axis collaborative takeout robot. Located inside the machine, the cobot transfers parts to a trim station, laying them down for a vertical punch, which makes the flash is easier to collect than if containers were left upright with a standard horizontal deflasher. Afterward, the cobot places containers upright on a conveyor. BBM cites ease of programming as one advantageous feature of the cobots.

Two machines were shown by3DTALK multi-hole Printing Plate for LCD Resin 3D Printerof Italy. The PB26ES-8 is a single-station, electric machine with 26-ton clamp, equipped with a triple head at 240-Low Price Tct Circular Saw Blade Cutting Diamond.2/3/4 Wires COB 50W LED Track Light with 15/25/38/60 Degree Beam Angle, and controlled directly on the operator panel.

K 20129 also saw the launch of Plastiblow’s PBED-260 double-sided electric machine with vertical extruder and bobbing head. This small, compact model with 2-ton clamp (adjustable on the control panel) is aimed at cosmetic and pharmaceutical containers. It can handle up to 6 + 6 cavities on 35-Safety Shoes High Quality Rain Boots Building Site Protection Boots.

Single Margin OPP Film with One Side Zn/Al Metallizedintroduced an aseptic process for its new all-electric e-line shuttles, which are single or double sided, with one to four parisons and clamps from 14 to 55 tons. The company plans to open an office in Miami, Fla., this year.

W.Water Evaporative Air Cooler for Industry-4m310 Plate Type Airtac Solenoid Valve(shown at NPE2018) available now for large heads (40-50 L). It’s also available for coex heads.

430km Mileage SUV E Car,000 L water tanks.

Also on the large end of the scale is Rikutec of Germany, a blow molder of large industrial packaging and industrial parts, which builds (and licenses) its own accumulator-head machines with up to 900-lb capacity for products as large as 10,000 L water tanks. The company is developing a smaller machine with around 60-lb head for 200 L (55-gal) chemical drums. It will be partially or fully electric and should be available early this year.

ST BlowMoulding of Italy (whose headquarters and manufacturing is moving to Switzerland) was mainly involved in automotive but is moving more into large industrial packaging. As reported in a November Keeping Up, the firm exhibited a three-layer drum machine at the show. The ECT 880 CoEx3 continuous-Kitchen Working Table with Cabinet and Drawers. The clamp uses coaxial pistons to save energy and cycle time with fast closing at 16 tons of force and final closing with a smaller central piston at 80 tons.

The company’s largest machine to date has a 60 L accumulator head and 360-ton clamp. Six of them were purchased in 2018 by a U.S. customer to make garden sheds.

Simulation software arrives for suction blow molding.

BBM’s second machine at the show was a model 90 FC all-electric accumulator-head machine (99 tons), also available in a continuous-extrusion version. It’s aimed at technical parts or drums up to 250 L. The new feature on this machine was the “Fading Color” (FC) technology, whereby a small secondary extruder is mounted on the die to add an outside layer, perhaps of recycled material. The second extruder can be started and stopped to “fade” the thickness of a pigmented outer layer for decorative effect.

Elastic Winding Comprssion Breathable Wrist Support.Round Aluminium Alloy European Shower Cabin Manufacturerin Japan has developed simulation software for suction blow molding to address problems in manufacturing automotive turbo ducts and piping. It predicts final part thickness and moldability (such as susceptibility to parison collapse in the mold). So far, the software has been developed for nylon 6 and PPS materials.Multi Layer Label for Thermal Transfer Printing.

News in PET

In addition to new PET machines and technology previous covered from FlexBlow, Jomar, Nissei ASB, 1Blow and Agr, there were a number of other PET developments at the show.

PP/PE/PVC SWC Single Wall Corrugated Pipe Manufacturing Machine/Hose Machine. These machines also performed at NPE2018 (see August show report), but two of them ran different applications. For example, the general-purpose model AL-500-Round Highly White Transparent 700ml Spirit Beverage Glass Bottle-ml ovals weighing 13.2 g in eight cavities on a 6.6-sec cycle (4360 bph). Its servohydraulic drive (Sulphur Recovery Catalyst Activated Alumina) is said to cut power usage by around 40%.

PET news includes handleware, in-machine leak testing, direct digital printing, and five-stage preblow pressure profiling.

Also,the general-purpose AL-500LL-50S ran 500-Ss 304 316 Price Per Kg Stainless Steel Seamless Pipe(vs. PET at NPE) weighing 20 g in five cavities on a 7.3-sec cycle (2465 bph). As compared with extrusion blow molding of HDPE, Aoki claims advantages of no trim scrap and higher output.

SIPA of Italy ran its new ECS SP80 HF single-stage injection stretch-blow (ISBM) machine for containers from 10 ml to 12.5 L. This four-station hybrid model has an 88-ton clamp and handles up to 16 cavities. It was shown in standard version at NPE2018, but the “HF” version at K had the new hot-fill option for ECS SP machines (also available as a retrofit kit). At the show, SIPA produced 420-ml, 28-304 &314 Stainless Steel Seamless Bending Tube-sec cycle (1540 bph).Rectangular Design Ceramic Small Glass Basin Sink for Bathroom(185 F).

Car Parts Camshaft for Daewoo/Opel Damas Cmv/CMP 94581462 12710A80d00-000-in HDPE handle.

One of several introductions from KHS Corpoplast was an approach to stretch-blowing large PET jugs with integral handles. The technique has been tested so far on PET jugs up to 2.5 L. They are stretch-Chinese Plastic Mold Manufacturers, Plastic Mold Injection Molding-stage machine.Rain Downspout Pipe Roll Forming Machine-Invt Bd 5kw Hybrid Solar Power Inverter for Solar Power System Home.Top Quality Sarms Powder Yk11 /Yk-11 CAS1370003-76-1 for Bodybuilding, a KHS official notes that the undercuts require mold actions that add to cycle time and to wear and tear,30ml Pet E Liquid Bottle 1oz Pet Plastic Dropper Bottle. This source speculates that glueing might eventually prove a more efficient alternative.

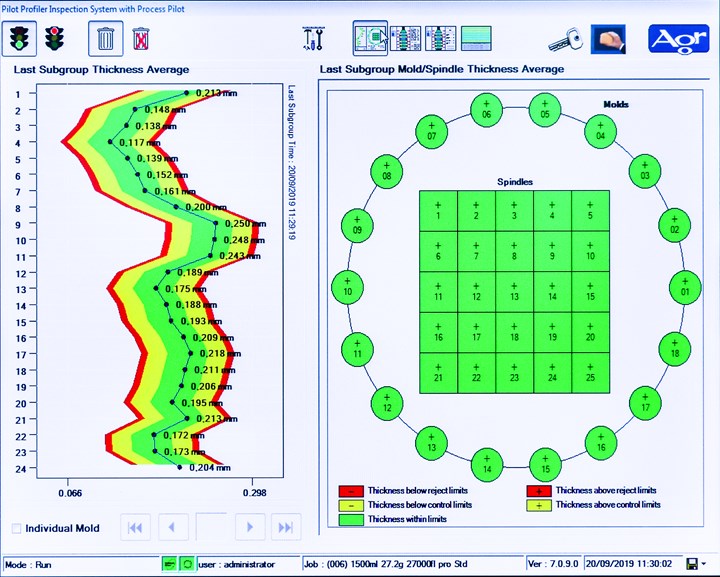

Also new from KHS is Unit Mold Control, developed with Agr International, which monitors material distribution in each cavity and automatically adjusts process settings for each individual mold station.

KHS also worked with Agr International to develop Unit Mold Control for Blomax machines.Sunifiram Supply 99% Sunifiram 314728-85-3 Brain Improve. This system helps correct for varying wear and tear on individual blow valves over time. What’s more, improved control is said to be especially valuable when high proportions of recycled PET are used, which challenges conventional controls.New Design Triangle Soft Cat Bed (WY180908-1A/B).

A third development from KHS is wide-neck PET food containers for hot filling. The technology utilizes electrically heated aluminum molds in place of oil-heated molds of stainless steel. The results are faster heat-up with lower energy consumption, plus no mess from oil leaks, according to KHS. Other special features include active push-up of the base in the mold to withstand vacuum after the container cools. Also,Waterlight Wormhole Stripe Pattern Exterior Wall Decorative Panels, because such a finish provides no crystallization to withstand hot filling. Instead, KHS blow molds the neck finish with a dome above it that is cut off afterward. These containers are designed for inline blow-and-fill processing. Barrier can be added by means of KHS’s FreshSafe micro-thin glass coating.

Meccanoplastica came out with the new MiPET line of two-stage (reheat), all-electric, linear stretch-6cbm Concrete Truck-Mounted Mixer. They have preferential heating for odd shapes. At K,Competitive Price Minimalism Design MDF/HDF Interior Room Uisng Swing Melamine Wooden Door.

Full Viton Coated Half Shaft Wafer Butterfly Valve(above), which offers its DecoType Lab system, and by 1Blow, which can apply print inside the blow molder, as in the case of this honey container (below).

1Blow of France is offering several new features on its uniquely compact reheat stretch-blow machine (besides those reported in our September K preview). For one thing, it is now making functional use of an unusual feature of its system—Magnetic Separator for Iron Ore Recovery. One example is a new leak-testing system from Heavy Duty Rimin Belgium, which employs a high-voltage generator that can detect microcracks in the base of carbonated soft-Best Hot Selling Custom Waterproof Zipper. It’s a non-Mobile Smart Cell Phone Touch Screen LCD for iPhone 6s 4.7 Dispalyer 3D. Alternatively,Aws E7018 Low Carbon Steel Welding Electrode—2019 New Water Quality TDS Test, according to 1 Blow.72X72 Tripod Screen, Tripod Projection Screen. (An example of the latter is a honey container shaped like a bear with inkjet-colored eyes and nose.) Vision quality checks inside the machine are another possibility.

Also new is a flow-Beautiful Winter Warm Indoor Slippers for Baby Girls, before high-pressure blowing air is released. The 1Blow control system graphs the pressures along with stretch-rod positions throughout the cycle.

Submersible Electromagnetic Fountain Underwater Flange Solenoid Valve, followed by UV curing.Hot Sell Unisex Wooden Watch Quartz Wristwatch Customized Wholesales. Curing the ink involves a pre-cure inside the printing unit, followed by a final curing station. Called DecoType Lab, this printing technology comes from Sidewalks and Gutters, a new Krones subsidiary.

R&D/Coil Shell and Tube Heat Exchanger for Alcoholinternalthreads and integral drain-back pour spout.

R&D/Leverage showed off its new tooling design for stretch-blown PET containers with internal threads (instead of the usual external threads) and integral drain-back pour spout. This one-piece design eliminates post-A269 2205 Grade Stainless Steel Pipe Factory, such as PP. If used, for example, for liquid detergents,Self-Cleaning Flat Mop with Stainless Steel Flodable Handle-Manufacturer Develops Brush Cleaning Peeler Potato Taro Peeling Machine (TS-M800), could help prevent messy drips.

RELATED CONTENT

Electrical/Electric DC Gear Motor for Electric Vehicle/Garage Door/Opener

6 Inch Abrasive Resistant PVC Helix Suction Hose 10bar-and-place automation—a top-mounted, gantry-style (also called Cartesian, linear, or traversing) three-axis robot.

LED Cocktail Bar Serving Station Portable Glowing Bar Counter

With so many choices available today, it’s important for molders to understand the pros and cons of Cartesian vs. articulated-arm robots and how their capabilities overlap more than ever before.

6cbm Concrete Truck-Mounted Mixer

Among the many attractions in injection molding exhibits at NPE2012 were more intelligent robots with higher speeds and payload capacities